Hairui Classroom | Successful Preparation of Graded and Oriented Porous Alumina Microspheres

Graded and oriented porous materials are employed in numerous fields due to their unique structures. However, high temperatures can easily cause pore collapse in these materials, affecting their performance. To address this issue, a team at the Institute of Chemistry, Chinese Academy of Sciences, specializing in microspheres, has prepared graded and oriented porous alumina microspheres with low density, high porosity, and low thermal conductivity through a method combining spray freeze-drying with heat treatment. These microspheres retained their graded and oriented porous structure even after heat treatment at 1200 °C. Additionally, COMSOL simulations demonstrated that the graded and oriented porous structure could enhance the material's thermal insulation properties. This work was published in the top journal Powder Technology (2024, Volume 444), under the title“Preparation of hierarchical directional porous alumina microspheres with high porosity, low density, and low thermal conductivity via spray freeze drying with heat treatment”。

原文链接:

https://doi.org/10.1016/j.powtec.2024.120027

图1

分级定向多孔氧化铝微球×100倍图,前驱体溶液浓度(a) 2 mol/L, (b) 1.5 mol/L, (c) 1 mol/L, (d) 0.5 mol/L 热处理温度 (1) 150 °C, (2) 900 °C, (3) 1200 °C

图2

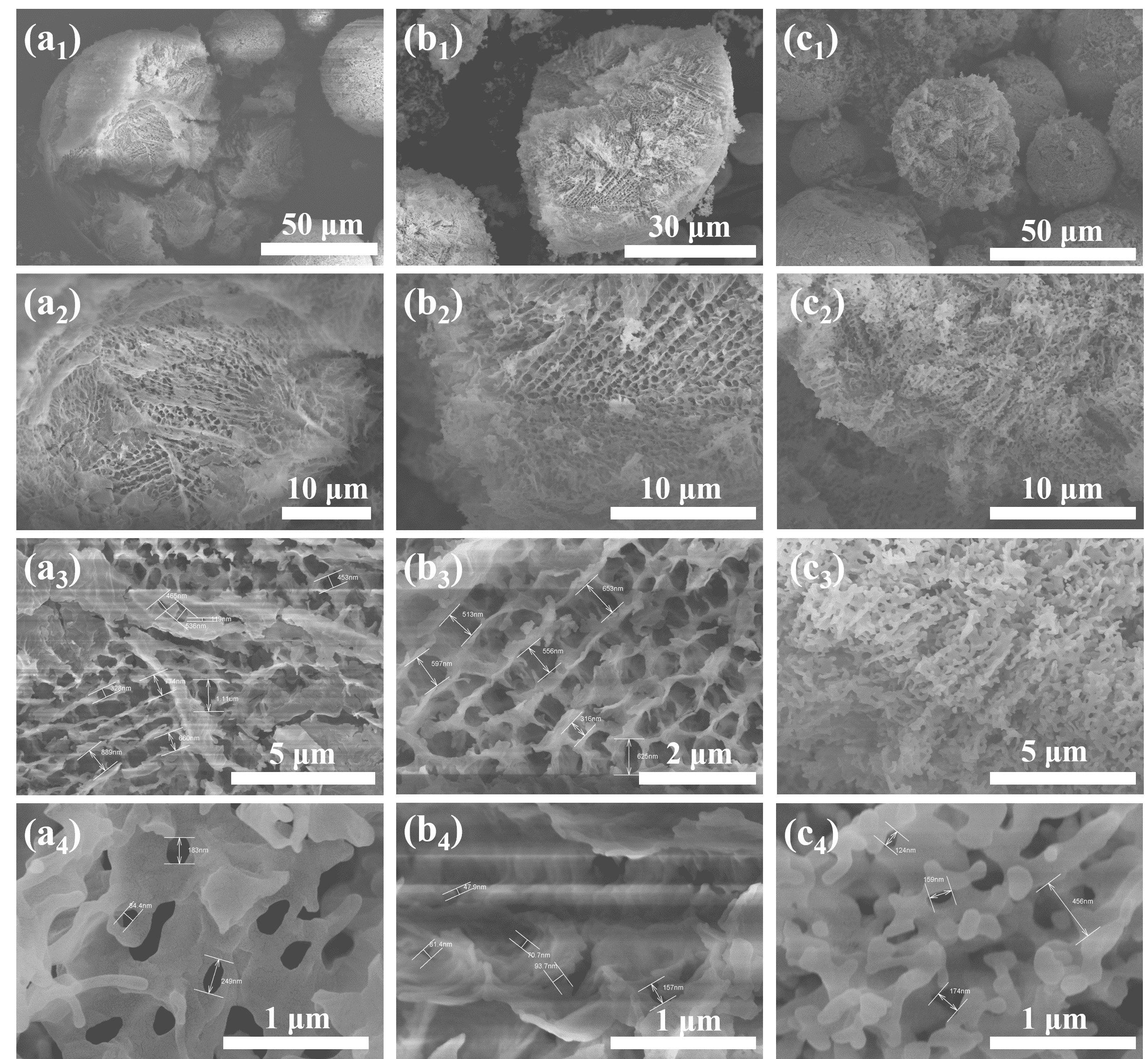

分级定向多孔氧化铝微球内部结构,热处理温度 (a) 150 °C, (b) 900 °C, (c) 1200 °C

This paper investigates the formation mechanism of alumina microspheres and their graded and oriented porous structures through single droplet freeze-drying experiments. The study reveals the formation of micrometer-scale channels from the outer surface to the center during the freeze-drying process, and nanoscale pores on the alumina framework resulting from the decomposition of aluminum salts during heat treatment. The microspheres prepared by this method have a bulk density ranging from 0.1260 to 0.5438 g/cm³, a true density ranging from 2.1204 to 3.7254 g/cm³, a porosity of 74.36% to 96.71%, and a thermal conductivity reaching 0.05109 W/m. Moreover, the graded and oriented porous structure remains intact even after heat treatment at 1200 °C. These alumina microspheres possess advantages such as low density, high porosity, low thermal conductivity, and structural stability at high temperatures, making them highly promising for applications in thermal insulation, particularly in high-temperature thermal insulation fields.